With the highly environment-friendly industrial world presently, companies are also getting more pressure daily in terms of optimizing their processes at the same time using less amount of energy and less of an environmental toll. Electric actuated butterfly valve is one of the major elements helping to achieve these objectives that provide intelligent flow control and good operation efficiency. Due to the implemented electric actuation, industries obtain a higher level of precision, automation, and sustainable value. This essay is about how these valves enhance energy efficiency, in what ways it fares in comparison with the use of electric actuated ball valves, and what the valves have to offer to present industrial systems.

What Qualifies Electric Actuated butterfly Valves to be Energy Efficient?

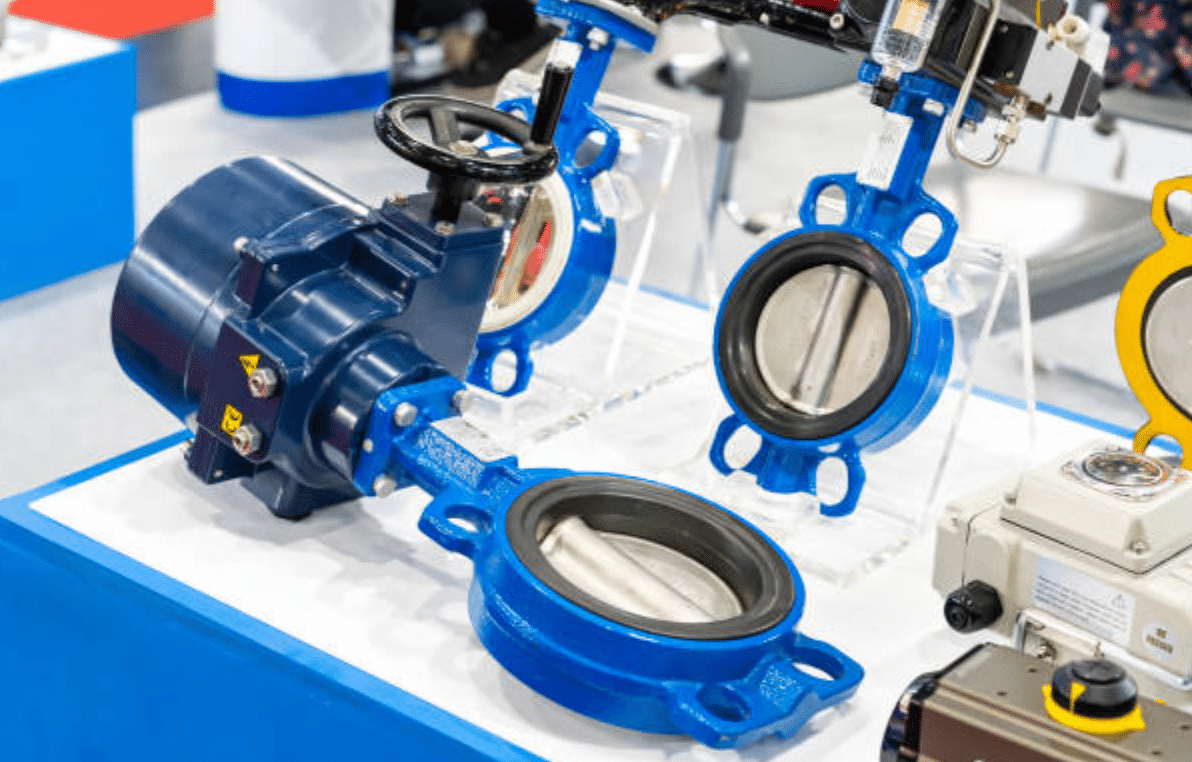

The electrically operated butterfly valves are a dimensional solution in the pipelines to bring about control in the flow of gases and liquids. They are designed with simplicity, namely, a rotating disc, which can be controlled via an electric actuator, which is why they are suitable for low-pressure, high-volume systems. As compared to pneumatic or manual valves, the electric actuated valves can draw energy intermittently at position change, greatly minimizing power usage over a given time.

These valves are made to function with a lower torque as compared to others particularly with ball valves or globe valves. Since the disk is relatively light and moves by only a few millimeters the energy requirement of the actuator is low. This suits them to systems that are used a lot but do not require regular adjustments in flow.

Besides, electric actuators make it possible to position the valve with an exceptionally high accuracy, being able to control the flow rates down to the immediate needs of the system. Such control assists in minimising overuse in pumping or energy use in circulation systems. When it comes to HVAC, water treatment, or chemical processing, improved flow can lead to quantifiable energy savings with a reduction in overall operations costs.

Electric actuation also eliminates the compressed air systems that notoriously behave with low efficiencies. Eliminating any air compressors and air compressor systems will help them reduce energy consumption immensely because it will lower the requirements of being and staying safe and making necessary repairs and maintenance processes less complex.

Electric Versus Ball Valves: How They Work and How Efficient They Are

Electric actuated butterfly valve as well as electric actuated ball valve are both indispensable in the context of automated flow control but they have different purposes and perform differently in various scenarios. The high sealing force and shut off strength of ball valves make them the most sought after valves in high pressure areas or valves where zero leakage is very important. However, butterfly valves would be more effective in cases where often modulation and lower pressure is needed.

On an energy efficiency perspective butterfly valve will usually take the ball game since it is made lighter and has a lesser torque needed. Ball valve actuators require greater force to turn the interior ball this may raise heavily on energy load especially when there is continual movement or having large diameter pipes.

Nevertheless, they can be both used in the energy-saving strategies once created and used appropriately. The most effective systems employ electric actuated butterfly valves in combination with electric actuated ball valves to optimize flow efficiency, sealing demands and energy requirements.

An example would be in a large industrial water system where butterfly valves are used to control the general flow in different areas of the system and ball valves are used to close at a particular point or emergency lines. This combination enables thorough automation and energy consumption control within limits.

Smart Industrial Systems Integration

The development of Industry 4.0 and intelligent automation technologies has resulted in additional requirements to flow control equipment. Electric actuators are natively digital, which means that at all costs they can be integrated in SCADA, PLC, and cloud-based systems.

This ecosystem is further supported by the use of electric actuated butterfly valves because they enable operators to remotely check the valve status, control the flow in real time and get alerts when a maintenance is liable to happen. This preventive control limits wastage of energy caused by improper flow or valve malfunction and allows planned repairs, further minimizing down months and spike in energy consumption.

On top of that, electric actuators are usually capable of position feedback, torque and temperature measurement. Such capabilities allow the system to achieve data-oriented decision-making as per real-time energy requirements. When it comes to the use of smart technologies, e.g. in district heating or industrial cooling, their implementation is directly reflected in savings on energy costs.

The operators can achieve it via their communication with digital twins or energy management systems and allow operators to take into account the various conditions of their operating routine and set up minimal energy use conditions. Electric actuated valves also permit a schedule to be programmed, and as such processes can only run during low demand times or when energy prices are advantageous, helping to increase the stability of the grid and economize costs.

Sustainable Value and Environmental Need

In terms of sustainability, electric actuated butterfly valves play different roles with regards to green operations. To start with, they consume less electricity than other systems, i.e, large-scale systems or remotely controlled systems. Second, they minimize the reliance on the non-renewable powered systems such as air compressors, which are energy-intensive and have high costs of maintenance.

Simpler in design and with fewer moving parts, these valves too have a greater life span. Maintenance costs are lower and there are lesser risks of oil leakage and costs of lubrication or cooling systems since they do not wear out as frequently. Its low-waste use of consumables and parts promotes a closed-loop strategy to equipment life cycles, cutting down waste and carbon pollution.

Another benefit is their suitability with renewable sources of energy. As the actuators will run on electricity, solar, wind, or hydro powered facilities will be able to time the valve actions to the green electricity providing a fully sustainable control loop.

Finally, the amalgamation of electric actuated butterfly valve and electric actuated ball valves helps industries to add energy-efficient solutions to various applications; either in clean water distribution, or to the flow of industrial gases as well as chemical transfer systems.

Conclusion

Energy efficiency has become one of the essential issues in contemporary industrial activity and electric actuated valves serve as one of the main factors in reaching it. Electric actuated butterfly valves in specific are characterised by low power requirements, control accuracy, and connectivity into intelligent systems. Whereas electric actuated ball valves are necessary in high-pressure and shut off, butterfly valves are a more energy-aware alternative to flow control and overall system efficiency.

Since the trend of industries shaping towards digitalization and sustainability is not going to stop, the request for intelligent, efficient, and qualified valve technologies is only going to increase. Electric actuated solutions aren t only giving operations a boost, but they are driving the future of the green industry.