New technologies are being embraced by industries for their improved dependability and space-saving features. One such technology is the EC axial fan for commercial refrigeration. Cold storage systems are being fitted with fans using electronically commutated motors as they replace outdated AC fans due to their better performance, speed control, and lesser size. Moreover, other systems like the superb filter fan unit can greatly enhance system functionality by optimizing airflow, cleanliness, thermal stability, and reliable operation in extreme conditions.

As for this article primary attention is given to food cold storage logistics and then broadens to the pharmaceutical industry in consideration of energy consumption, space usage, system integration, and total system optimization.

Why EC Axial Fans Are Ideal for Commercial Refrigeration

The EC axial fan incorporates brushless DC motors with built-in electronics, leading to enhanced benefits. Other benefits include:

Use up to 70% more efficient

Real-time adaptive speed adjustments

Quieter operation in areas where noise is a concern

Smaller form factor because of fewer external components

These are especially helpful for commercial refrigeration equipment that requires continuous cooling and has high operating costs. These fans enable systems to reduce energy costs and maintenance downtime while improving temperature control.

EC axial fans regulated by cooling loads, in contrast to constant-speed conventional fans, work intelligently. This self-regulating feature streamlines utility expenses during low demand periods, improves compressor dependability, and lowers overall cost of ownership. When paired with a filter fan unit that provides superior dust, grease, and airborne contaminant filtration, the total cost of ownership decreases dramatically.

Space-Saving Features of Modern Cold Chain Facilities

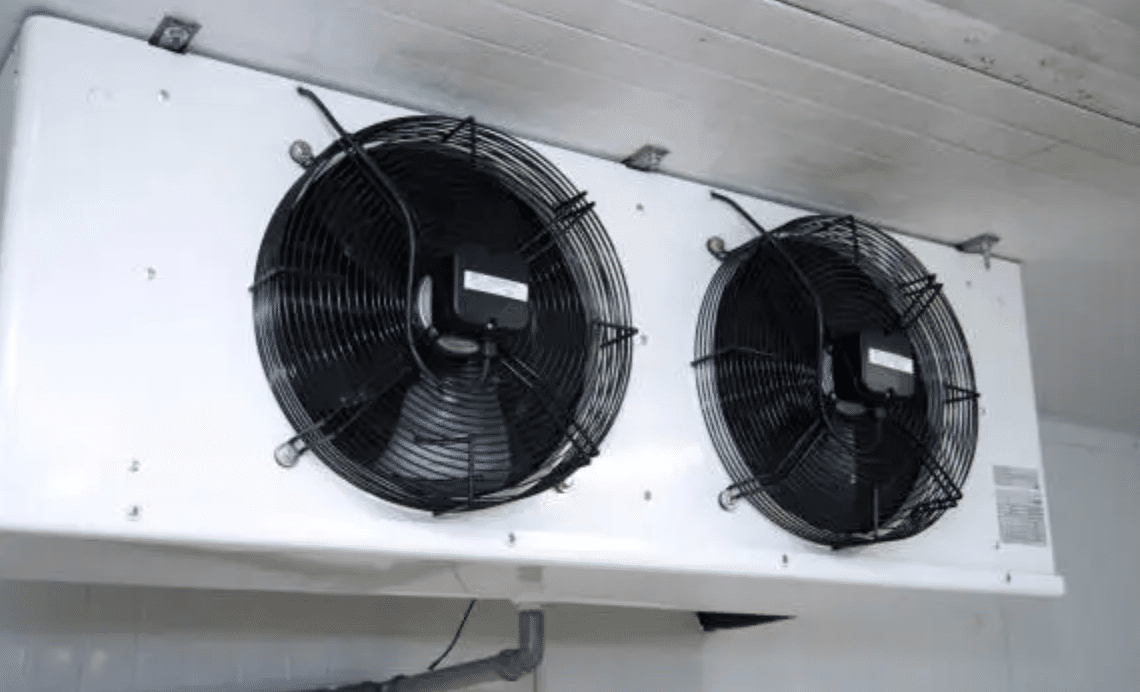

The advantages of EC axial fans, particularly their capacity to enhance airflow in constricted areas, are often taken for granted. Consider modular cold rooms, refrigerated display cases, and mobile storage units. These are designed for B2B refrigeration but space is often tight.

With the EC axial fan, commercial refrigeration units have the advantage of being both lightweight and compact. Integrators with simplified systems benefit from a reduced installation footprint and bulky external controllers and additional hardware are no longer needed because of direct plug-and-play capability.

Installation of a filter fan unit helps maintain system cleanliness and also helps prevent internal clogging. This increases the spacing minimization between the coils and panels that are at risk of airflow obstruction and heat buildup. Such optimization is critical in food retail where sightlines and convenience to refrigerated display units influences sales performance.

Smart Control, Smarter Refrigeration

Intelligent systems are standard in the B2B setting. With modern building automation systems (BAS), programmability and compatibility of EC axial fans provide more advanced functionalities that make them indispensable within today’s digitized ecosystems.

With these fans, control is usually done through:

0-10V analog inputs

PWM (pulse width modulation) signals

Modbus or other serial communication protocols

These functionalities allow for adaptive control of airflow, remote diagnostics, and continuous evaluation. This leads to reduced servicing costs, fewer manual checks, and faster problem detection.

The advantages are enhanced considerably when used with filter fan units. The filter fan safeguards the internal components from contamination, which assists in maintaining consistent airflow and thermal exchange crucial for sensitive temperature products.

In one sentence: EC axial fans for commercial refrigeration and filter fan unit systems integrate effortlessly to provide intelligent, responsive, and low upkeep cooling for industrial operations running continuously.

Supporting Sustainability Goals and Regulatory Compliance

Sustainability is now an imperative dynamic of a business as opposed to a procurement checkbox sitting under the “corporate social responsibility” umbrella. Governments are implementing more aggressive efficiency frameworks, such as Europe’s ErP Directive and America’s mandatory ENERGY STAR testing.

These principles aim to dictate the construction of EC axial fans, which also consume less electricity than traditional fans, as well as generating less noise and heat. The majority meet RoHS directives and are built to comply, or surpass, global standards for cost-effective energy utilization.

Meanwhile, filter fan units enable companies to minimize the frequency of deep cleans and filter replacement, along with water and chemical usage. Together, these technologies offer businesses a dependable means of attaining internal sustainability KPIs or obtaining green building certifications such as LEED or BREEAM.

Use Cases in Various Sectors

It is interesting how EC axial fans are adopted in refrigeration systems in B2B sectors.

Retail Refrigerated Cabinets.

EC fans help with proper airflow circulation during door openings. During the circulating air filter fan units, EC fans reduce the maintenance downtime by increasing the intervals for cleaning the condenser coils.

Cold Chain Logistics.

In frozen transport containers, and refrigerated vehicles, EC axial fans help with circulation and airflow at a very low power draw. The low weight also helps reduce overall vehicle fuel consumption and weight.

Food and Beverage Manufacturing.

Exposed stainless steel cooling surfaces within high humidity and particle environments are vulnerable to condensation. The use of EC fans with filter systems helps mitigate this issue and improves the cooling surface’s lifespan.

Pharmaceutical Storage.

Vaccines and biologics storage needs precision cooling. EC axial fans maintain temperature uniformity within cross sectional racks or compartments due to precise speed controls, ideal for these applications.

Data centers with incorporated cold aisles.

Some hybrid designs use refrigerated air to cool specific server racks. EC axial fans provide effective control of the airflow in small high heat densely packed configurations.

Conclusion

The traditional view that the EC axial fan for commercial refrigeration and filter fan units is only applicable to small businesses or niche sectors is changing. It is now being adopted by companies seeking smarter, decarbonized, efficient, and scalable cooling technologies.

Design engineers for modern refrigeration systems, facility managers responsible for several cold rooms, or HVAC contractors delivering integrated ZED solutions for the food, pharma, and cold chain logistics industries—these professionals have EC fan technology high on their specification list. It addresses performance and compliance requirements and provides a buffer against escalating energy costs and environmental regulations for mid to long-term operational planning.