As the renewable energy transition accelerates, the solar sector is zeroing in on advancements that boost operational efficiency, enhance safety, and provide granular monitoring capabilities across PV systems. At the heart of this optimization lies the PV combiner box, the unassuming enclosure that channels the output of multiple solar panel strings into a single production line. These units are now smartening up, equipped with next-gen capabilities that speak directly to the regulatory, economic, and performance demands of commercial and industrial solar installations. For stakeholders like EPC contractors, asset developers, and, notably, an EV charger manufacturer that bundles electricity production and vehicle fast-filling, familiarity with the newest combiner technology is a prerequisite for ensuring that installations deliver as promised over their expected lifespans.

This overview surveys the freshest developments in PV combiner units, spotlighting smarter monitoring systems, next-tier safety enhancements, and the on-the-rise mandate for rapid shutdown mechanisms. For each of these pillars, the payoff is the same: greater transparency, lower risk, and unmistakably higher confidence in operational continuity, whether the end customer is a rooftop logistics hub, a fleet depot, or a solar-charging hybrid bus station.

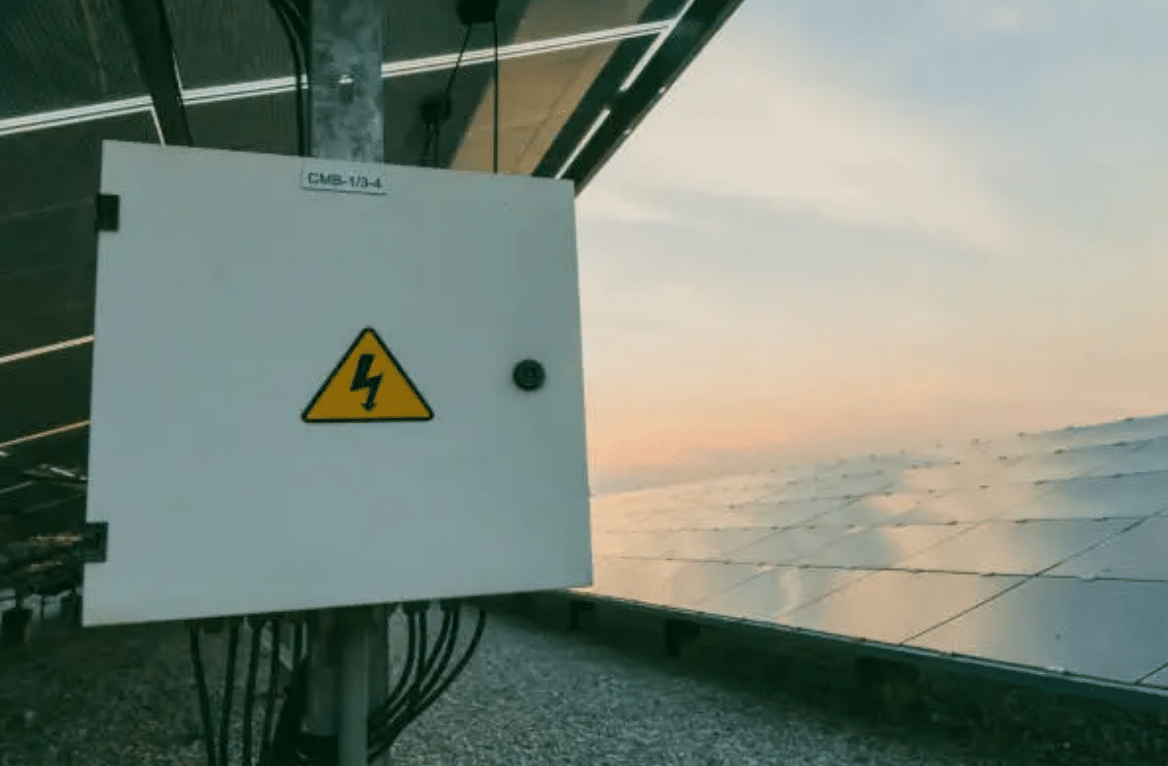

The Evolving Role of PV Combiner Boxes in Modern Solar Systems

PV combiner boxes remain the hub where multiple solar strings converge into a single, cohesive DC feed. While their foundational duty was combining circuits, the past decade has seen their purpose deepened: beyond tidy cable assembly and primary surge protection, they now serve as the strategic junction in increasingly ambitious PV architectures.

Contemporary solar plants routinely interface with multi-layer energy ecosystems—high-performance energy management platforms, stationary battery arrays, and high-power electric vehicle chargers. Some manufacturers of the latter now build solutions in which the combiner modules and the chargers synchronously divert, store, and deliver solar output, thereby trimming both investment and energy losses. Such convergence necessitates platforms that deliver real-time visibility, fault diagnostics, smart disconnection, and tiered code compliance on a single footprint.

From the vantage of B2B sector stakeholders—large development firms and utilities—evolving combiner architectures mitigate unplanned outages, boost yield through intelligent string balancing, and simplify the spiral of audit and certification. The net effect on the project lifecycle is resilient, predictable, and economically decisive, confirming that the field of module interface technology is no longer a passive commodity but a strategic enabler of energy intelligence.

Advanced Monitoring Capabilities for Real-Time Performance

Modern PV combiner boxes mark a leap forward with on-board, live monitoring. Where earlier models merely shielded circuits, today’s devices embed intelligent hardware that continuously logs voltage, current, and string health metrics with micrometre-level timing.

Operators stand to benefit in concrete ways:

- Early Fault Detection: The ability to monitor current string by string lets teams spot weak modules or creeping shade before losses escalate.

- Improved Asset Management: By streaming performance data to a central server, teams cut the frequency and cost of field inspections across sprawling sites.

- Enhanced Efficiency: Analytics surface trends that balance output over the entire array and reposition production for added yield.

Details transmitted to management systems equip developers and O&M providers with a forward-looking maintenance calendar, shrinking the risk of surprise outages and protecting the internal rate of return. In an environment where every operating hour counts, retrofit and new projects alike are including smart monitoring as a baseline requirement.

Safety Enhancements: Protecting Assets and Personnel

Safety across utility-scale solar plants demands constant, incremental improvement. To meet that reassurance standard, new PV combiner boxes are now designed with multi-layered protection that guards both hardware and the human teams tasked with maintaining high-voltage systems.

Contemporary safety enhancement packages feature the following devices:

- Surge Protection Devices (SPD): Safeguards delicate electronics against direct strikes and voltage spikes by diverting excess energy.

- Next-Gen Fuses and Circuit Breakers: Detects irregularities and disconnects circuits in milliseconds, averting cascading outages and system collapse.

- Arc-Fault Circuit Interrupters (AFCI): Identifies and interrupts dangerous arcing at the source, greatly diminishing the likelihood of electrical fires.

For enterprise users, these innovations ensure alignment with global safety regulations, lower the potential for liability claims, and boost the investment attractiveness of solar projects. Engineering, procurement, and construction (EPC) firms, project developers, and operations and maintenance (O&M) contractors can proceed with confidence when presenting offerings that satisfy both statutory and underwriting criteria.

Rapid Shutdown Technologies for Compliance and Safety

In several jurisdictions, the code mandates that photovoltaic (PV) installations feature rapid shutdown capability in order to safeguard emergency personnel. As a result, this function has emerged as a cornerstone of innovative PV combiner box design.

By deploying rapid shutdown circuitry, system operators can render the array safe within seconds, thereby minimizing the risk of accidental electrocution during maintenance or when fire crews respond to an emergency. This capability is especially vital in expansive commercial rooftop and utility-scale arrays, where transient overhead circuits could be extensive.

For commercial partners, the rewards include:

- Code Adherence: Satisfy national electrical and fire safety directive in their entirety.

- Personnel Protection: Shield maintenance crews and emergency responders from persistent voltage hazards.

- Enhanced Market Position: Availability of code-compliant solutions elevates systems integrators’ attractiveness to both financiers and customers.

As renewable energy systems become ever more interconnected with the grid and energy storage, the addition of rapid shutdown systems is now a fundamental requirement, rather than an optional enhancement.

Why Smart PV Combiner Boxes Are a Strategic Priority

For any solar-oriented B2B firm, deploying cutting-edge PV combiner boxes is more than a checkbox for regulators; it is a decisive business move. These units now bundle continuous monitoring, robust safety protocols, and instantaneous shutdown, and the resulting advantages impact the bottom line.

- OPEX Drop: Built-in analytics cut the need for frequent site visits and prolong the lifecycle of components.

- Faster Payback: Heightened protection and streamlined operation lower the risk of unscheduled outages while steadily boosting output.

- Standards Ahead: Future-ready functions conform to the next wave of safety regulations, safeguarding investments against obsolescence.

- Synergy with EV Chargers: Aligning solar with fast-growing electric mobility becomes straightforward as combiners link generation to vehicle supply systems, creating integrated energy hubs.

Companies that embrace these technologies firmly establish themselves as forerunners in dependable, compliant, and modular energy offerings.

Conclusion

PV combiner boxes have long since evolved past their original function of simply housing cables and fuses; today, they are sophisticated, safety-oriented, and code-compliant modules that sit at the heart of today’s solar systems. Advanced features like real-time monitoring, built-in protective mechanisms, and rapid shutdown capabilities are reshaping these units into essential components for delivering high-efficiency, future-proof solar projects.

For B2B stakeholders, these modernization gains guarantee not just the sustained performance of installations, but also alignment with global safety norms and the accelerating market need for converged solutions, such as coupling solar output with electric vehicle charging. EPC firms, solar developers, and EV charging original equipment manufacturers alike must embrace the newest capabilities of combiner boxes in order to retain a leading position as the renewables sector continues to evolve at an unprecedented pace.