The focus in the fast, high-paced world of packaging is on precision, efficiency and versatility. Be it printing on flexible films, paper or foil, the accompanying equipment is the key to the high level of the production and compatibility. The stand out among other alternatives in the industry is stack flexo printing machine, which has been found to be a force to reckon with in most packaging companies. This paper discusses what should be in mind when buying a package printing machine, and what the strengths and characteristics are on why stack flexo presses are one of the best.

Making the best press decision is not only a print quality issue it has a direct effect on delivery time frames, economics and flexibility of your brand. As consumer demands and quickly changing custom needs mount, your packaging activity has to be highly efficient and agile. The stack flexo equipment provides a suitable integration of precision and flexibility, which is why these machines are perfect candidates to businesses that are innovative and solid.

Why Flexo Printing Machinery Stack In An Edge

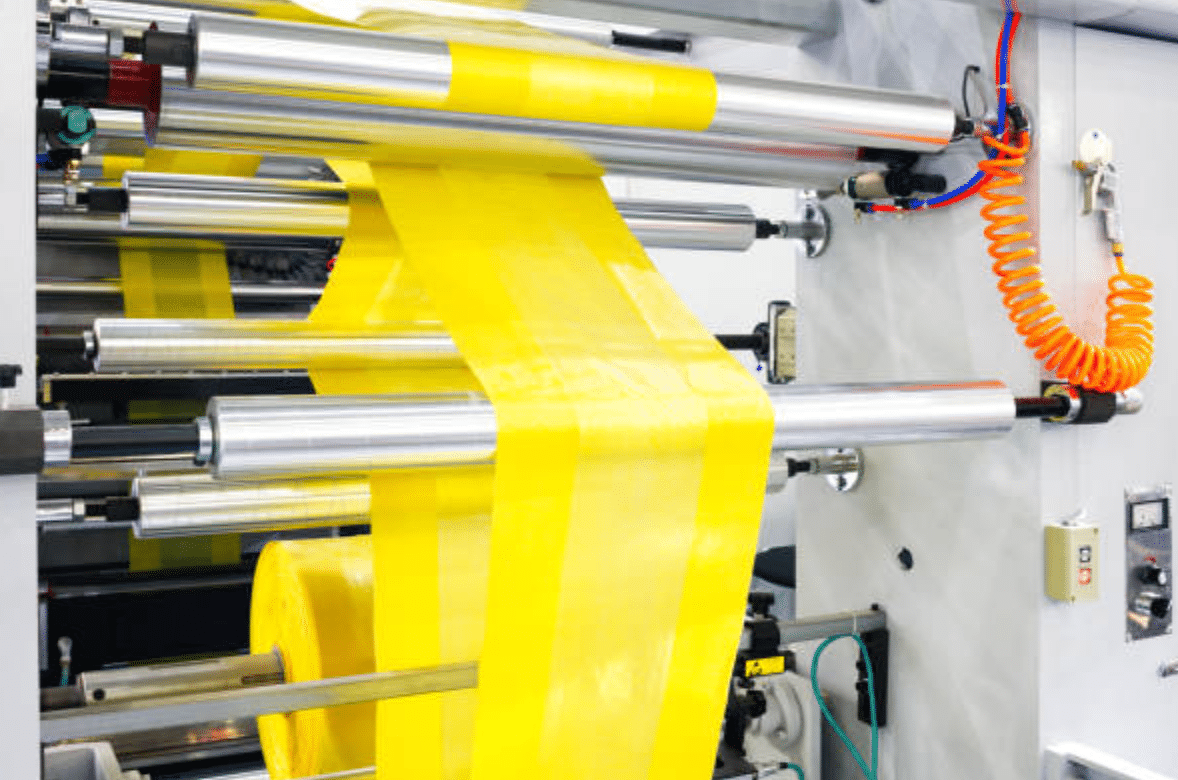

Compared with central impression (CI) presses, stack flexo presses have individual print stations that can be set vertically or horizontally, each color station can be independently controlled. The layout is particularly helpful to those kinds of jobs that need to be flexible on the color configuration, or kind of material. Efficiency can also be enhanced by the possibility to print on both sides simultaneously on the substrate.

This form of package printing machine is becoming trendy as its machine style won the affection of many firms that require a medium point between performance and cost-effectiveness in their production line. Stack flexo allows high color accuracy, maximum ink transfer efficiency and versatility in a broad scope of substrates, right down to thin plastic films and kraft paper. The flexibility is such that it is suited in converters that serve more than one market, such as food packaging, retail, and industrial markets.

Also, stack flexo systems consume relatively smaller space in the floor when compared to other flexo machines, which is very beneficial to facilities with tight facilities. Others also include inbuilt tension control systems and integrated web guides which speed up the setup process and serve to cut down wastages. These features make the operations flow much easier in an environment where speed and material changeover are of high importance without compromising on the integrity of what is printed.

The Important Characteristics to Consider before Purchasing

It is important that when selecting a package printing machine one pays attention to quality of printing, ease of running, quickness and reliability among others. Features such as servo motors to allow tight registration, tension control systems to allow precise handling of thin films, and quick change components that allow reduction in downtime should be sought. Ink viscosity control, web alignment systems and drying elements (built in) are also essentials in long production runs.

Press frame and components build directly influences the level of vibration and accuracy of printing. A well developed mechanical concept minimizes noise and wear and leads to throughput and reduces maintenance costs. Moreover, UV inks, water-based and solvent-based ink compatible machineries allow your operation more flexibility in coping with the environmental and regulatory situation.

Another factor that you need to consider is the degree of automation provided by the press. Touch screen machines, job remembrance, and automatic ink cleaning do not only save on labor time but also increase the job accuracy. Advanced tension controls in conjunction with the ability to monitor in real-time enables a production to continue with very little error occurrence, even during complicated jobs.

Once you think about investing; be long-term in the thinking. A machine which gives you modular expandability will enable you to accommodate an increase in your production capacity as your business demands.

Integration with Existing Production Lines

Modern packaging efficiency is not created by individual pieces of equipment but by the ability to integrate the line. In each case, it does not matter whether you want to connect your printing machine to slitter, laminator, or bag-making equipment, your stack flexo printing machine must provide the option of real-time communication between upstream and downstream machines.

One of the latest models contains the IoT enabled diagnostics, the performance software. This allows operators to follow the machine health, optimize the production processes, and automate the schedules of the orders. Such digital capabilities decrease time spent on the setup procedures and accelerate delivery without loss on quality in the settings where custom packaging is required.

On the fly adjustments to tension settings, drying times and the print sequence can make a colossal difference in overall line efficiency. A stack press with easy-switching capabilities in regard to the width of material as well as the print repeat length is imperative to those businesses with a multi-format production base.

Other than hardware, the software interface must be friendly and scalable. It will save time and prevent mistakes because all operators have a single dashboard to change the level of ink, view print preview, or control the time of maintenance. All these help in increasing OEE (Overall Equipment Effectiveness) and in reducing the downtime in productions.

Service Support and Operational Training

The most sophisticated package printing machine will not do its wonders without sufficient technical support and lesson training. When considering a machine, inquire of the service model used by the supplier, they provide packages of preventative maintenance, are they available when troubleshooting, can they provide quick spare parts delivery? These do influence the machine uptime and ROI directly.

The training also plays an important role. Trained attitude will help the operator optimise performance, minimise wastes and detect problems even before they escalate into high costs. Seek vendors with comprehensive induction courses, use manuals as well as continuous learning programs. The very presence of a long-term service agreement or even a warranty is a good indication that the producer believes in their equipment.

It is one of the greatest reasons why several enterprises prefer using a stack flexo printing machine as their ideal machine when printing packages without necessarily focusing on its steadfast performance but the after-sale service which maintains limited interference and the maximum working period.

Another thing you ought to consider is easy access to service centers, multilingual customer care in your operations all over the world and online documentation. One might think these are all small issues till they come to a standstill in production or in case of troubleshooting they require immediate solutions.

Conclusion

A stack flexo printing machine is not just an equipment, it is an investment in the development of your firm, its efficiency, and the quality of print. Since the amount of personalized, environmentally friendly, and quick-turn formats of packaging is on the increase, the decision in terms of the choice of a package printing machine is one step toward the strategic direction.

Considering print possibilities, automation options, substrate options, and support, one will be able to match their business in the competitive environment of the ever-changing market. You are reportedly upgrading your existing system or you just happen to be a newcomer to the flexo printing market, and this guide provides you with a good base where you can make an informed choice in purchase that bears long-term value.

The packaging sector is currently developing at a high pace, and an increasing number of enterprises are aiming at automation, customization, and environmental friendliness. It is a wise investment on modern stack flexo press to put you in a position to grow in the future, get better in your bottom line and provide consistent quality in every package you print.