Water is one of the most destructive forces in a residential or commercial setting, capable of compromising structural integrity in a matter of hours. When a plumbing failure occurs, the difference between a minor inconvenience and a catastrophic renovation often comes down to the expertise of the response team and the quality of the tools they employ. It is a high-stakes race against time where preparation meets precision, requiring a blend of veteran intuition and modern technology to stop the flow and secure the property. Property owners rely heavily on the swift action of professionals specializing in leak prevention to mitigate these risks effectively.

The initial moments following a pipe burst or a sewer backup are often defined by panic and confusion, but for a seasoned plumbing crew, this is the time for calculated mobilization. The “damage escalation curve” in plumbing emergencies is steep; water wicking into drywall, soaking into subfloors, and threatening electrical systems means that every minute of delay translates into exponential repair costs. Consequently, the most effective service providers operate with a crisis management mindset, utilizing dispatched vehicles that are essentially mobile warehouses equipped to handle a multitude of scenarios the moment they arrive on site.

Beyond the immediate rush to shut off valves, the logistical side of plumbing emergency management is equally vital. A technician’s ability to resolve a crisis is often limited by the quality and availability of the components in their inventory. While a homeowner might scramble to a local hardware store for a generic patch, industry experts maintain a ready stock of industrial-grade couplings and heavy-duty clamps designed for high-pressure scenarios. Understanding the vast array of necessary components, ranging from simple gaskets to complex full-circle repair sleeves, can be illuminating, and browsing the extensive inventory on the blair supply website offers a glimpse into the specialized equipment required to tackle these disasters effectively.

The Science of Speed: Why Reaction Time is Only Half the Battle

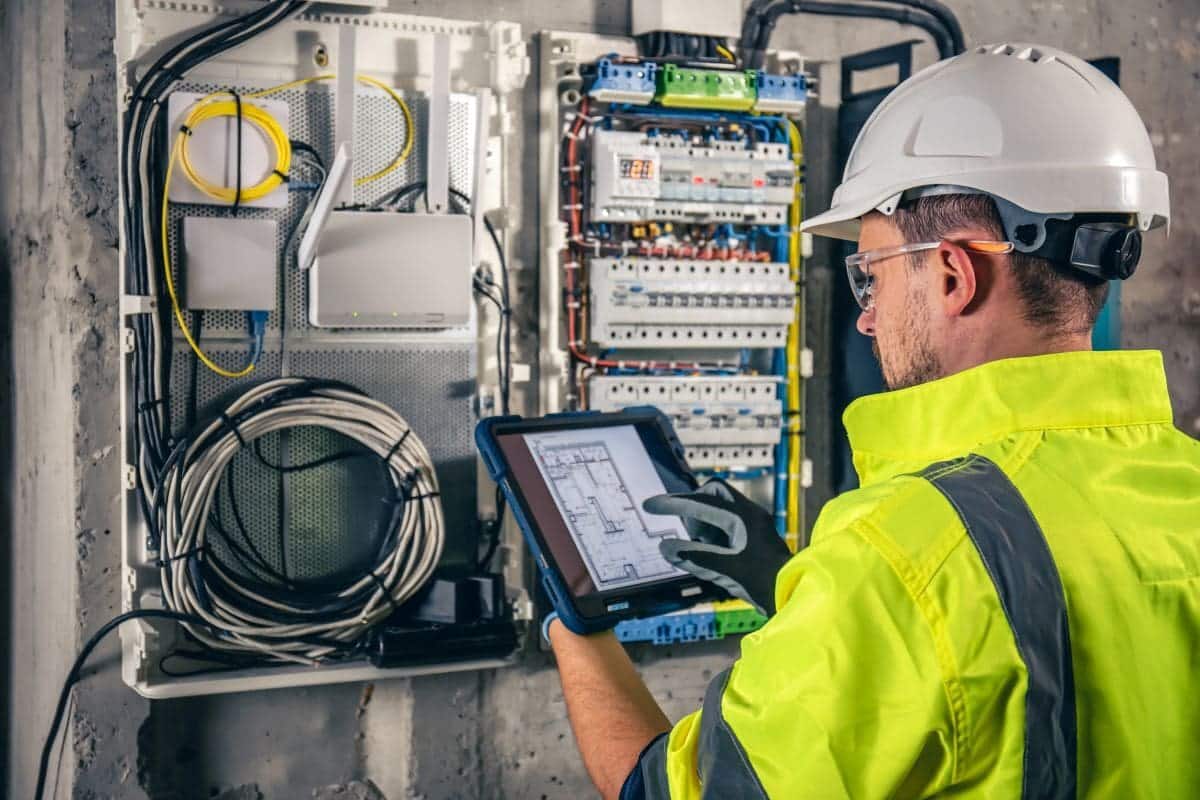

Arriving quickly is a prerequisite for success, but the speed that truly matters is the time it takes to accurately diagnose the root cause of the failure. A rapid response team that arrives in twenty minutes but spends four hours cutting holes in the wrong walls is ultimately less effective than a team that utilizes targeted diagnostics. Modern crisis management in plumbing has moved away from educated guessing and toward data-driven assessments. This shift reduces the “exploratory destruction” that was once common in the industry, preserving the building’s aesthetics while focusing efforts strictly on the problem area.

This efficiency is driven by a deep understanding of hydraulic systems and the physics of water flow. Technicians assess pressure drops, auditory cues, and visible moisture patterns to form a hypothesis before they ever pick up a wrench. This analytical approach ensures that when physical work begins, it is surgical and decisive, minimizing the disruption to the occupants and the building infrastructure.

Seeing the Unseen: The Era of Non-Invasive Diagnostics

The most significant advancement in modern plumbing repair is the ability to see inside the infrastructure without excavating the foundation or tearing down drywall. In the past, locating a slab leak or a deep sewer blockage was a destructive process that involved jackhammers and guesswork. Today, advanced diagnostic tools allow professionals to visualize the interior of pipes and the spaces behind walls with crystal clarity, transforming the repair process into a precise operation.

Sewer cameras are perhaps the most recognizable of these tools, featuring high-resolution lenses mounted on flexible fiber-optic cables that can snake hundreds of feet into a line. These cameras do more than just spot a clog; they reveal the condition of the pipe walls, identifying cracks, root intrusion, or offset joints that could cause future failures. Similarly, hydrostatic pressure testing allows technicians to isolate specific sections of a plumbing system to determine if they are holding water, narrowing down the location of a leak through a process of elimination that is rigorous and exact.

The Right Tool for the Job: Industrial-Grade Solutions

Once the issue is located, the focus shifts to the hardware used to resolve it, and this is where the gap between amateur fixes and professional repair becomes most apparent. In a crisis, the temptation to use temporary, easy-to-apply solutions like tape or putty is high, but these materials are rarely sufficient for pressurized water lines or heavy-duty waste systems. Professional plumbers rely on engineered mechanical fittings that are designed to withstand the specific stresses of the environment, whether that involves thermal expansion, ground shifting, or high water pressure.

A prime example of this is the specific selection of repair clamps based on pipe material and diameter. A clamp designed for a ductile iron main operates differently from one intended for PVC or copper residential lines.

- Stainless Steel Bands: These provide corrosion resistance and high tensile strength, ensuring the repair does not rust out over time.

- Gridded Gaskets: High-quality clamps often feature rubber gaskets with a grid pattern, which bites into the pipe surface to prevent the clamp from sliding under pressure.

- Full-Circle Seals: Unlike a patch, a full-circle clamp encompasses the entire circumference of the pipe, providing uniform support and sealing power that prevents the pipe from bursting elsewhere along the weakened section.

From Temporary Triage to Permanent Peace of Mind

One of the most critical decisions a plumbing professional makes during a crisis is determining whether a repair is a temporary triage measure or a permanent solution. There are instances where a “Redi-clamp” or a similar rapid-deployment device is used to stop an active leak immediately, stabilizing the situation so that the water can be turned back on for the building’s occupants. However, a responsible technician knows that a clamp, while durable, may not always be the final answer if the underlying pipe is deteriorating due to age or corrosion.

The transition from a temporary fix to a permanent cure often involves analyzing the structural integrity of the surrounding pipe. If a pipe has pinpoint holes caused by electrolysis or chemical corrosion, a single clamp is merely a band-aid on a larger wound. In such cases, the crisis management plan must evolve into a capital improvement plan, where sections of the plumbing are scheduled for replacement. This honest assessment protects the property owner from recurring floods and the stress of repeated emergencies.

The Human Element: Why Expertise Trumps Hardware

Even the most sophisticated diagnostic cameras and the strongest stainless steel couplings are useless without the skilled hands to operate and install them. The human element remains the cornerstone of effective plumbing crisis management. It takes years of experience to know exactly how much torque to apply to a bolt to seal a leak without crushing the pipe, or to interpret the grainy image on a sewer camera monitor correctly.

Safety is also a paramount concern that requires professional oversight. Plumbing emergencies often involve contaminants, high pressure, and electricity in proximity to water. A trained professional navigates these hazards with protocols that protect the household and the structure. Ultimately, the combination of advanced technology, industrial-grade parts, and seasoned expertise provides the only true safeguard against the chaos of a plumbing disaster.